A strong surge in activity is likely for the global diameter edge grips market owing to increasing demand from aerospace, automotive, electronics, industrial sectors that require manufacturing. Analysts forecast a very high CAGR over the next decade, with developing markets from Asia and Europe having significant effect on this growth trend.

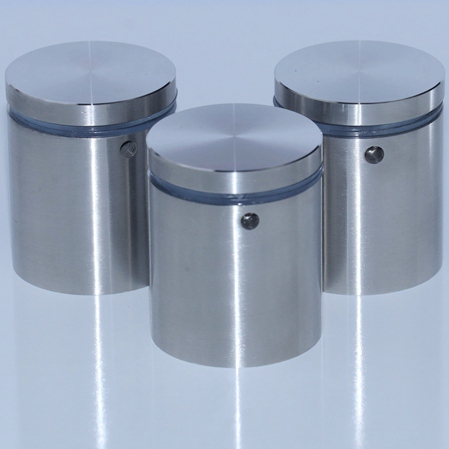

With more industries pushing for quality and efficiency, the demand for diameter Edge Grips has escalated tremendously as these components have become important parts of modern machinery and processes. The grips offer safe use and reduce center of gravity and therefore improve the automation processes in high power machines.

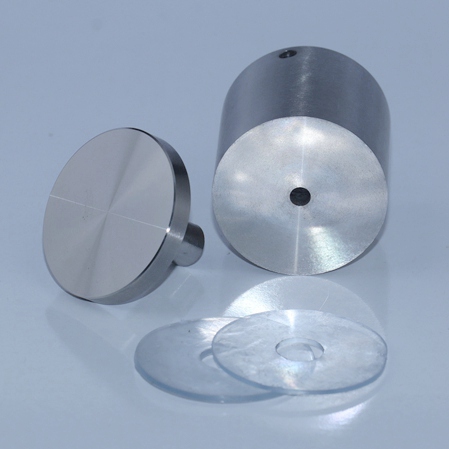

Professional use of the diameter edge grips is penetrating in niche markets such as robotics, medical, and precision engineering. Their ability to be tailor made to customers for fit for use has also made them become a market favourite to professionals. Making sure the said custom fit parts are provided or developed would be companies such as DILANGSI Hardware Products Factory.

Manufacturers’ understanding of the industry and replacements services has made them continuously make new products that are in demand and meet market industrial criteria. In this regard, the foresight of DILANGSI preserves its strong position as authorized partner for professionals manufacturers everywhere.

In the automotive and aerospace industries, diameter edge grips are essential for improving the performance of the product. The two industries have components that are expected to be strong but have low weight. Diameter edge grips are able to fulfill these requirements by providing stable attachments and smooth motion in structural assembly and automation equipment with mass production.

DILANGSI Hardware Products Factory has been involved in several automotive and aerospace projects where it’s provided grips of professional quality which have improved efficiency as well as minimized chances of production errors. As electric vehicles as well as higher grade aeronautics become more and more popular, the need for reliable grip technology is bound to increase.

Robotics and Industrial Automation involves a lot of precision for proper coordination of various processes. Diameter edge grips have facilitated the improvement in the working of robotic arms, automatons as well as conveyor belts hence are widely used in the automation industry.

DILANGSI has the needed grasp in creating grips with remarkable materials and designs as needed by her clients thus meeting the dynamic requirements necessitating the use of automated industries. Due to working with robotics and automation companies, DILANGSI improves production processes making them easier and faster thus enhancing technology at various industries.

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now