Introduction:We specialize in producing glass brackets suitable for various scenarios. Our advertising screw series logo stands come in different specifications to meet different needs. I believe we can provide reliable and efficient solutions.

stainless steel standoff screws are a type of fastener made of stainless steel that are typically used to create a fixed distance between two objects. They are usually threaded and can be screwed into corresponding holes to create a fixed distance between the objects, ensuring consistent alignment and stability. These screws are widely used in many fields such as electronic assembly and furniture manufacturing to ensure the precise positioning and alignment of parts.

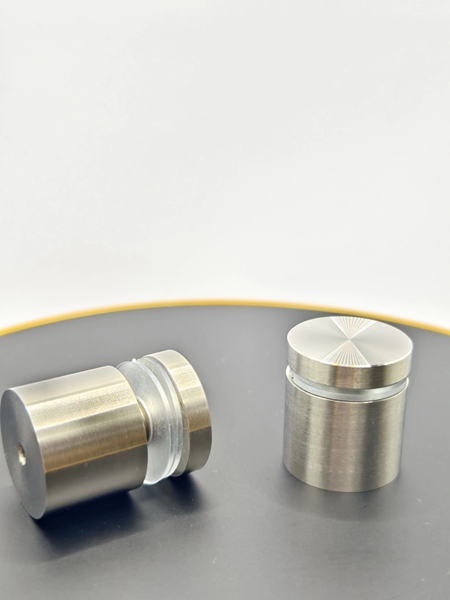

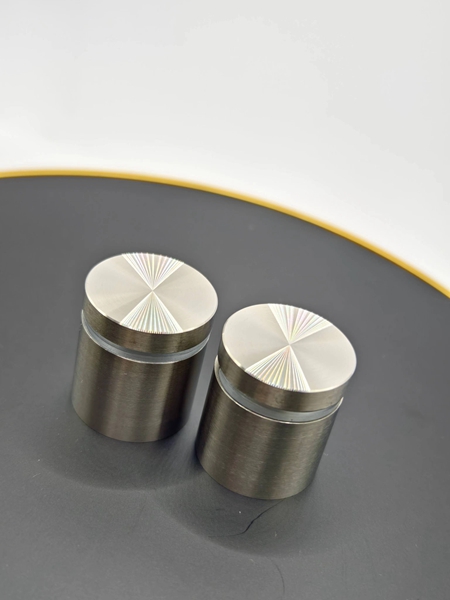

Our stainless steel standoffs are perfect for any modern and contemporary design that requires a sleek and functional support system. Made from high-quality stainless steel, these standoffs are built to last and are perfect for glass panels, signs, art pieces, and more. They are available in a range of sizes and finishes, including satin, mirror, allowing you to choose the perfect aesthetic for your project.

Our Stainless Steel Standoff are easy to install and can be used in a variety of applications, including residential and commercial projects. They provide a modern alternative to traditional mounting hardware and allow for a floating effect that adds depth and sophistication to any installation. Plus, they are durable and sturdy enough to support heavy glass pieces and can withstand harsh weather conditions.

So if you're looking for a reliable and stylish way to mount glass, look no further than our standoffs. With their sleek design and durable construction, they're sure to provide the perfect accent to any modern and contemporary project.

| Finish: | Satin Brushed |

| Product Number: | CF25-25S |

| Inside/Outside: | Inside Or Outside Use |

| Diameter: | 25mm |

| Distance From Wall: | 13/20/25/30/45/60mm Multiple Sizes Can Be Customized |

| Cap Height: | 5mm |

| Shape: | Cylinder |

| Process: | Stainless Steel Signage Standoff Screws |

| Material: | Stainless Steel |

| Solid/Hollow: | Solid |

| Length: | Different Length Available,You Can Also Customize The Size |

| Other Diameter: | 12mm / 16mm / 19mm / 25mm / 30mm / 38mm, Etc. |

| Customized: | Can Provide Customized Graphics |

| Material Grade | 201or304 |

| Factory Nature: | China Manufacturers Suppliers Factory |

With our understanding of the uniqueness of hardware and stainless steel products, customization is one of the focuses of our services to meet the specific needs of customers.

Material: Stainless Steel Standoff Screws are made of stainless steel, which has excellent strength and corrosion resistance, and can maintain stable performance in harsh environments.

Surface treatment: The surface is satin brushed, which not only improves the appearance, but also reduces friction and scratches, and enhances durability.

Size diversity: A variety of sizes are available, including 13mm, 20mm, 25mm, 30mm, 45mm and 60mm, which can be customized according to specific needs to meet different assembly requirements.

Structural design: Usually a solid structure, ensuring its stability and reliability when bearing large loads.

Thread type: The thread design is precise, ensuring a close fit with the corresponding components and providing a stable connection.

Scope of application: Suitable for a variety of application scenarios, including but not limited to electronic equipment, mechanical assembly and furniture manufacturing.

Architectural Signage Installation

Stainless Steel Standoff Screws can conveniently and elegantly permanentize architectural signage within corporate offices, retail outlets, or universities. Easily done with their simple shape and a reliable fastening system, they not only provide guidance but also a professional representation to your signage by providing a floating appearance.

Museum and Gallery Display Mounting

Stainless Steel Standoff Screws have an advantage when mounting glass panels, plaques or artwork in museums and galleries. This way, the beautiful works will be prominently visible without being covered in the mounting devices, and Stainless Steel Standoff Screws suit best for such purposes where aesthetics and practicality are equally sought.

Glass Partition Walls in Offices and Restaurants

Stainless Steel Standoff Screws have routinely been applicable as safeguards for glass forced walls in modern-day offices and posh eating places, maintaining an open and sophisticated atmosphere. The high-quality material used ensures durability even in a busy environment with a super high turnover rate.

Public Facility Sign Mounting

In the case when some directional signs, exhibition nameplates, and information displays needed to be secured, hospitals and airports, as well as shopping facilities have found to be working with Stainless Steel Standoff Screws. These Stainless Steel Standoff Screws are able to keep the sign in a secure position and close off the target area from unauthorized adjustment and invasions while keeping the polished look of the sign.

Construction and Assembly of Booth Structures and Exhibits

Stainless Steel Standoff Screws find their place in building exhibition stands and in displaying panels during trade fairs. Due to their variety and ease of installation, they enable fast assembly and disassembly and are, therefore, ideal for exhibitors.

Cleaning: Regularly wipe the surface of the screw with a clean cloth to remove dust and dirt to keep its surface clean and bright.

Rust prevention: When used in a humid or corrosive environment, a thin layer of anti-rust oil can be applied to enhance its corrosion resistance.

Check the thread: Regularly check the integrity of the thread. If it is damaged or worn, it should be replaced in time to ensure the reliability of the connection.

Storage environment: The screws should be stored in a dry and ventilated environment, avoiding contact with acidic or alkaline substances to prevent corrosion.

Avoid over-tightening: During installation, avoid over-tightening the screws to avoid thread damage or material fatigue.

Regular maintenance: For screws that are used for a long time, it is recommended to perform regular maintenance and inspection to ensure their performance and safety.

DILANGSI Hardware factory also has an experienced team and is equipped with advanced machinery and technology,Having rich experience in foreign trade exports, enabling us to efficiently and quickly produce high-quality products.With our understanding of the uniqueness of hardware and stainless steel products, customization is one of the focuses of our services to meet the specific needs of customers.

About Product Delivery | |

| Supply Ability | 10000 Pieces Per Week |

| Package | Cartons, wooden boxes, pallets, packaged according to weight and customer requirements |

| FOB Port | Shipping according to customer needs |

| MOQ | 100 pcs |

| Delivery Time | Samples in 7 days, cargo in 30 days, the time depends on the quantity the order |

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now